TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

Plastic Piping Material Properties

How to begin selecting the right piping material for your application

Careful consideration is needed when selecting piping material to ensure the material properties meet the requirements of the intended piping application.

Each individual plastic pipe material has its own profile of characteristics that affects the material's suitability for an intended application. The most common characteristics across most applications that will need to be considered are;

• Material's temperature profile

• Resistance to aggressive medias

• Impact resistance

• Connection methods

The correct selection of piping material will increase the longevity of the pipeline and help avoid many problems that may arise during the pipe system's lifetime. In the following article we explain a little more about each of the common considerations that should be made.

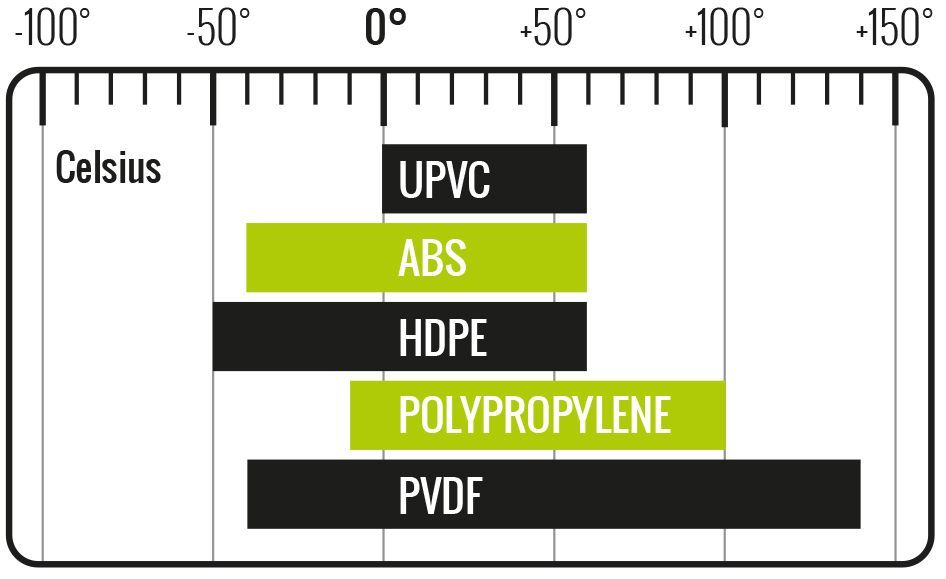

WORKING TEMPERATURE RANGE COMPARISON CHART

MATERIAL CONNECTION METHODS

| Material | Connection Method |

|---|---|

| UPVC | Solvent Cement |

| ABS | Solvent Cement |

| Polypropylene | Fusion |

| HDPE | Fusion |

| PVDF | Fusion |

Temperature Ranges of Plastic Pipe Materials

We have compiled the chart above to demonstrate the working temperature range within which each plastic pipe material is expected to function normally, before its effectiveness as a piping material becomes compromised. Working temperature or operating temperature, is the temperature to which the material is exposed for sustained periods of time during operation.

As you can see from the temperature comparison chart there is a lot of variation in the temperature ranges between materials. There is, however, an overlap across the range of plastic piping materials, between 0°C and 60°C. So if the intended application has maximum and minimum temperatures within this overlap range, then there are multiple options for suitable materials. As the required temperature range of a piping system moves beyond the 0 to 60°c range, then options become more limited; ABS or HDPE being more suited to lower temperatures, whereas Polypropylene and PVDF being more capable of handling temperatures over & above 60°C are suitable options for higher temperatures.

Relationship between temperature and pressure

All pressure ratings are provided based on the piping of water at 20°C, and as temperature increases the plastic material will soften and be less capable of handling high pressures. Each pipe material is subject to what is known as pressure-derating, where the maximum pressure for each pressure rating & pipe material can be calculated for given temperatures. See here for derating information

Connection Methods

Simply put, this is the method that the fitter will use to make joints in the pipe system.

Solvent cement jointing is the easiest and most well-known pipe jointing method and consists of using a "glue" to join pipe to fittings. Technically, it is a cement, that dissolves the surface of the material on the outside of the pipe and the inside of a fitting and when they are pressed together the surfaces become welded together, creating a leak-free & pressure-resistant joint.

Fusion Methods

Certain plastic piping materials, by their design are resistant to solvents and therefore cannot be solvent cemented and must be fused together by an alternative method. Fusion is actually a broad term, as there are multiple fusion methods, but each fusion method involves applying energy to the surfaces of the pipe and pipe fitting, which softens them. As the surfaces are pressed together they set and become fused together to form the pressure-resistant joint.

In the instances of Socket fusion & Butt Fusion, it is thermal energy that is used to soften the surfaces allowing them to be fused together. The connecting surfaces are heated to melting and the connecting faces are then pushed together precisely to create the joint.

Then there is also Electro-fusion and IR Fusion, which employ electricity and infra-red respectively, to form the joints.

Whichever fusion method is employed in making the joints for the pipework, it will involve special fusion equipment. This, in turn makes the use of these pipe materials that require fusion, not so desirable to the amateur pipe fitter or to the professional in less demanding applications, as it tends to be easier to make solvent cement joints.

Chemical Resistance Profiles

If you are intending to use the pipe to convey any fluid other than water, then it is always advisable to check the suitability of the piping material. Remember to check the resistance data for

all of the chemicals, with which the pipeline will be expected come into contact.

Each plastic pipe material varies in its ability to resist different chemicals at differing temperatures.

It is really beyond the scope of this article to present all of the information regarding chemical resistance data for every material, as you may imagine, these lists of data are quite large. So, having read the previous sections relating to temperature and connection method; we suspect that you are already thinking of a particular material for your pipeline project and we have prepared links to the chemical resistance information on our site for each individual material;

Choose a material to see chemical resistance data

All information provided in this article is intended as a preliminary guide only. The information contained herein does not constitute advice and some subjects briefly mentioned in this article may need further research to be fully understood. Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.