TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

Linear Expansion of Plastic Pipe

How temperature changes affect plastic pipe & what you need to consider to avoid problems within the piping system

All solid materials expand and contract with changes in temperature. How much expansion and contraction occurs with the same temperature change differs between materials. The Linear Co-efficient of Expansion is the rate of change in one unit of length per each unit of change in temperature. Plastic pipes, such as PVC and ABS, exhibit a significantly higher linear coefficient of expansion (LCoE) than other materials such as metal.

This higher LCoE means that plastic pipes are more prone to expansion and contraction with changes in temperature than metal pipes are. Therefore, if you're used to working with metal, different clipping and support methods are required for plastic pipes, traditional pipe clamps may be designed for metal pipe. Even minor temperature fluctuations can cause plastic pipe to expand or contract significantly.

| Material | LCoE in mm/m °C |

|---|---|

| PVC-U | 0.08 |

| PVC-C | 0.07 |

| ABS | 0.1 |

| PP (Polypropylene) | 0.18 |

| PE (Polyethylene) | 0.2 |

LCoE - How to calculate the actual change in a length of material for expected temperature changes

Expressed simply, linear expansion is the phenomenon of an object's increase in length due to its rise in temperature. The LCoE is the rate of change in one unit of length per each unit of change in temperature. Using the LCoE, the expected length change in a given length of pipe material can be calculated.

Example Calculation:

At installation; a 6 Metre length of PVC-U pipe is precisely 600cm at 20°C, if the temperature increases to 50°C there is an increase of 30°C. Using the LCoE from the chart above we can calculate;

6

Metres

x

30

degrees of temperature change

x

LCoE of

0.08

= 14.4mm (1.4cm)

The result shows that the example pipe length is now: 601.4cm

Note: If the ambient temperature is higher at the time of installation than the temperature during operation, the pipe material will contract at the same rate. So for the example calculation, we would subtract the LC0E calculation, as shown, from the original material length which would equal a new length of 598.6cm for a drop in temperature of 30 degrees.

The significance of thermal expansion in pipelines

The change in a pipe length can cause damage to the system if not properly accounted for (taken up). If fastened rigidly then that extra length has to go somewhere and will apply force to rigid fasteners and joints and create stress fractures in the piping material. There are two main ways in which expansion can be taken up; one is a natural way with the incorporation of expansion loops or utilising existing bends to create flexible sections and the other is in a designed way with the use of compensators. The most popular way of dealing with thermal expansion are natural ways, so we'll discuss the use of these natural methods mostly throughout this article.

How to avoid damage due to thermal expansion

Proper selection, positioning and installation of pipe clips

Whilst pipe clips are not in themselves a complete method to handle thermal expansion, pipe clips will form a very important part of the overall success of any method that you decide to incorporate. Almost all instances of system damage due to expansion and contraction occur when the pipe is clamped too tightly. Therefore, it is essential to use appropriate pipe clips designed specifically for plastic pipe that allow for free linear movement of the pipe.

The primary purpose of a pipe clip is to support the pipe and prevent it from bowing under the combined weight of the pipe and the material being transported inside. The secondary purpose is to support heavier pipe system fittings such as valves and filters on either side, which will put more strain on the pipe due to their increased weight.

If plastic pipes are tightly gripped and fixed in place, the pipe cannot expand or contract, which can lead to stress fractures, leaking joints, and system weakening. Therefore, plastic pipes should be gently held or supported to allow for free movement through the pipe clip if expansion or contraction is necessary.

It is also crucial to gently support pipes if there is a risk of water hammer from the sudden start-up of a pump or the opening or closing of a valve. This provides a place for the vibration to dissipate.

What Pipe Clips Should I Use on My Plastic Pipe?

There are several options for pipe clips for plastic pipes, including rigid plastic clips and rubber-lined clips. Rubber-lined clips are more flexible in terms of the distance they can be placed from a surface. However, they should only be fitted loosely to allow the pipe to move between them.

Allowing Flexible Sections

What is a flexible section

Flexible sections are the most common method of incorporating a way to deal with linear expansion within a plastic pipe system. Flexible sections can occur naturally at any branching or change in direction of the pipeline. So much so, that it is often the case that people aren't even aware that linear expansion is a potential problem, as they have naturally created a flexible section; until the time that lack of flexibility or improper application of clips causes an issue to arise. The key here is to consider the positioning of clamping & fixing points, so as to take advantage of the natural flexibility of the plastic pipe material and so as to not inhibit movement at changes in direction of the line.

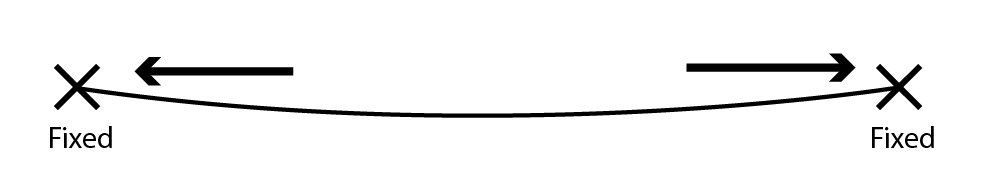

Visualise a single length of plastic pipe that is fixed rigidly at both ends. In this scenario the rigid fixings could be an inlet and outlet. As the pipe expands, that extra length will need to go somewhere and so you will notice the pipe is no longer straight it will curve to allow for the extra length; pressure is now being constantly exerted on the rigid fixings and possibly causing damage, as the pipe wants to be able to relax at this new increased size.

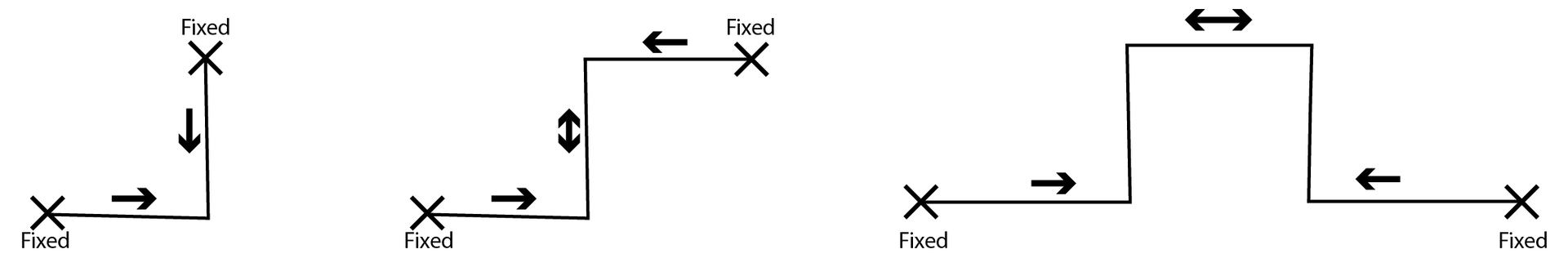

Creating a flexible section

In the following examples of piping configurations, the inclusion of angle joints significantly alters the way the pipeline deals with thermal linear expansion. You'll notice that the elastic energy stored in the system, that was causing constant stress in the example above, is now being diverted away from the rigid fixing points and is shared over multiple joints. The simplified diagrams below are slightly exaggerated for the purpose of demonstrating energy direction and do not accurately demonstrate the flexibility of the plastic pipe which would further take up some strain in real life examples.

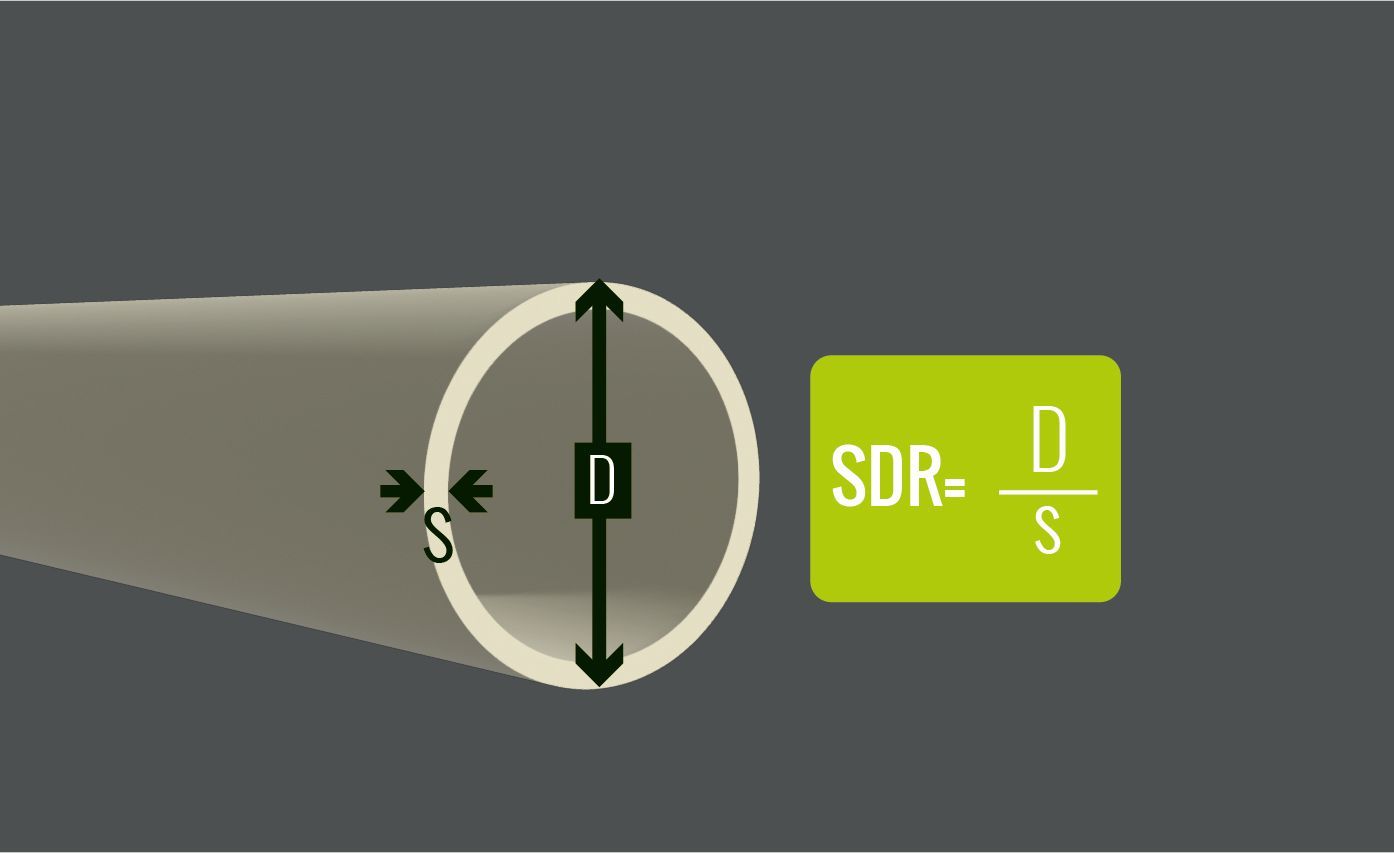

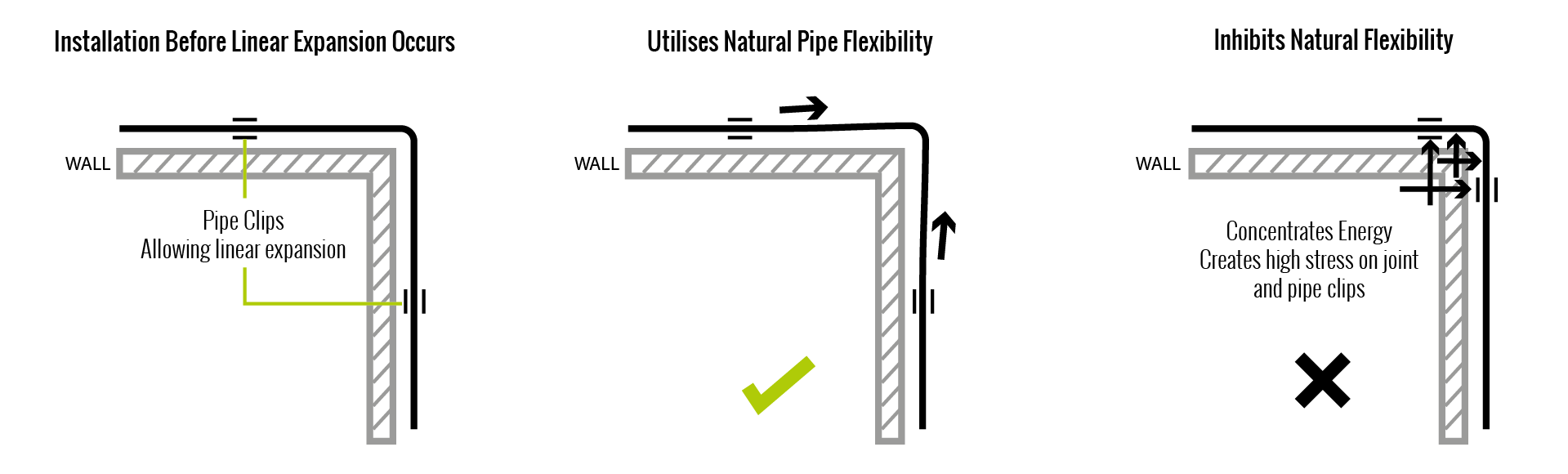

Using Pipe Clips in Flexible Sections

Remember, flexible sections are meant to be flexible and therefore careful consideration is needed when positioning pipe clips and they should be employed in a fashion that utilises and doesn't inhibit the natural flexibility of plastic pipe. One major factor in deciding pipe clip spacing in areas where flexibility is required is the flexibility of the actual pipe itself; which is determined by the pipe material, pipe diameter and pipe wall thickness. A smaller diameter pipe with a thinner pipe wall will be more flexible over a shorter length and therefore clips can be used at more frequent intervals in flexible sections. The diagrams below demonstrate the importance of utilising the plastic pipe's natural flexibility, so as not to cause damage from stress.

Pre-stressing the pipe system

What is pre-stressing

Pre-stressing is the act of building stress into the pipe system at the time of installation, so when the pipe system reaches an expected operating temperature, the stress is eased due to the changes in material length. Take our example from the beginning of this article, a 6m length of UPVC pipe is expected to expand by 1.4cm, when the temperature is increased by 30°c; so if the pipe system's operating temperature is 30°c higher than that of installation, then fitting a length that is shorter by 1.4cm will be the correct size during operation as the pipe material will expand with the increase in temperature. The pipe system will encounter the linear stress only when it is not operating and contracts to the original length with the decrease in temperature.

When to consider pre-stressing

It may be that the expected change in length due to temperature change can be factored in to the design by pre-stressing the pipe system. This will depend on different factors, which should be considered first. If you have a system that is to constantly run at an even temperature above or below that at which it is installed, then pre-stressing could be an option; as for the majority of the service time, the pipe system will be experiencing less stress and would only be under stress as temperature changes back to that at the time of installation, when being maintained, for example.

Pipe systems that will experience frequently fluctuating temperatures will not benefit from pre-stressing and linear expansion will need to be accommodated within the pipe system using an alternative method, such as flexible sections or compensators.

Pre-stressing may have an adverse effect when the actual system temperature changes negatively from the installation temperature. As an example; If a pipe system is expected to operate at 50°C and is installed at 20°c with pre-stressing to account for the 30 degree rise in temperature, but then the pipe system is subjected to temperatures of 0°C, this is now a 50 degree change from the temperature at which the system is relaxed, and is a whole 20 degrees beyond the point at which the system has been planned to experience the stress. This extra stress may now be beyond the capability of the pipe to flex & adjust to accomodate the contraction, causing stress fractures and damage to the system.

Summary

The simplest and possibly the most effective points to take away from this article are:

• Keep thermal expansion in mind at the design stage of the pipe system.

• Use plastic pipe clips designed for plastic pipe and do not overtighten. Allow for linear movement due to expansion

• Do not inhibit the natural flexibility of plastic pipe in angled joint areas that can be utilised to take up thermal expansion naturally.

- Keep in mind where the pipe length will want to expand and the joined perpendicular pipes may flex to accomodate.

- Proper positioning of clips will need to be considered, so as not to inhibit flex.

We have tried to keep this informative article purely about pipefitting without it becoming overly mathematical or a lesson in physics, hopefully it will have helped to answer some basic questions regarding the expansion of plastic pipe within a system, however there is more to know on each subject that we have touched on. If you need to be more accurate with your calculations, further reading is definitely recommended. If it is required, further information can be provided, so please do not hesitate to contact us at

Pipe Warehouse UK.

Important Note: The data on Linear Coefficient of Expansion of each polymer, as shown in the chart at the top of this article has been provided to us by one of our major suppliers of pressure pipe; however, different manufacturer's production methods may result in slightly different figures.

All information provided in this article is intended as a preliminary guide only. The information contained herein does not constitute advice and some subjects briefly mentioned in this article may need further research to be fully understood. Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.