TECH TALK

TECHNICAL INFORMATION AND INFORMATIVE HELP ARTICLES

UK Pipe Marking - A guide to BS 1710:2014

Understanding pipe marking requirements and standards in the UK.

Is it a legal requirement to mark pipes in UK?

YES. Under the Health and Safety (Safety Signs and Signals) Regulations 1996 it is a legal requirement in the UK to mark pipes, where there is a risk to health and safety. These regulations make no specific mandate to follow any particular standard, but it does state that the marking needs to be clear and concise and recommends using a recognised standard; such as BS1710.

What is BS1710?

BS1710

is a set of

standards used for marking pipes

published by the British Standards Institute. BS1710

specifies the colours and supplementary information for the identification of pipes conveying fluids/gases in

above and below ground installations. It also includes ducts for ventilation and conduits that carry electrical services. BS1710

is the

most widely recognised

system across the UK for identifying pipes and whilst these specific standards are not mandated by general UK law, some local authorities or governing bodies may specifically refer to the standards, therefore making them a legal requirement within the geographical jurisdiction or within a particular industry or context.

For help in understanding the legal implications see this article from the BSI

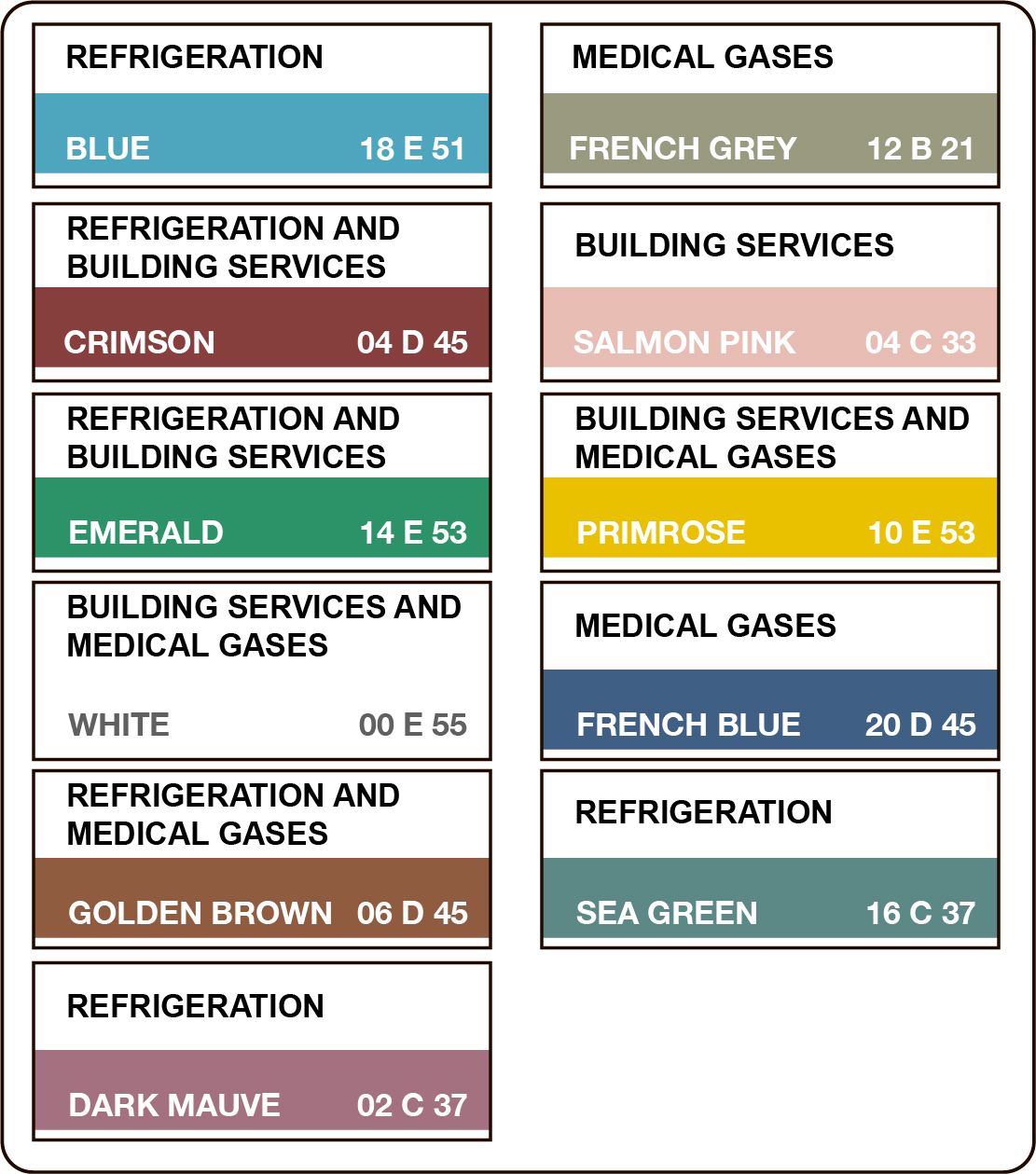

Identification through colour

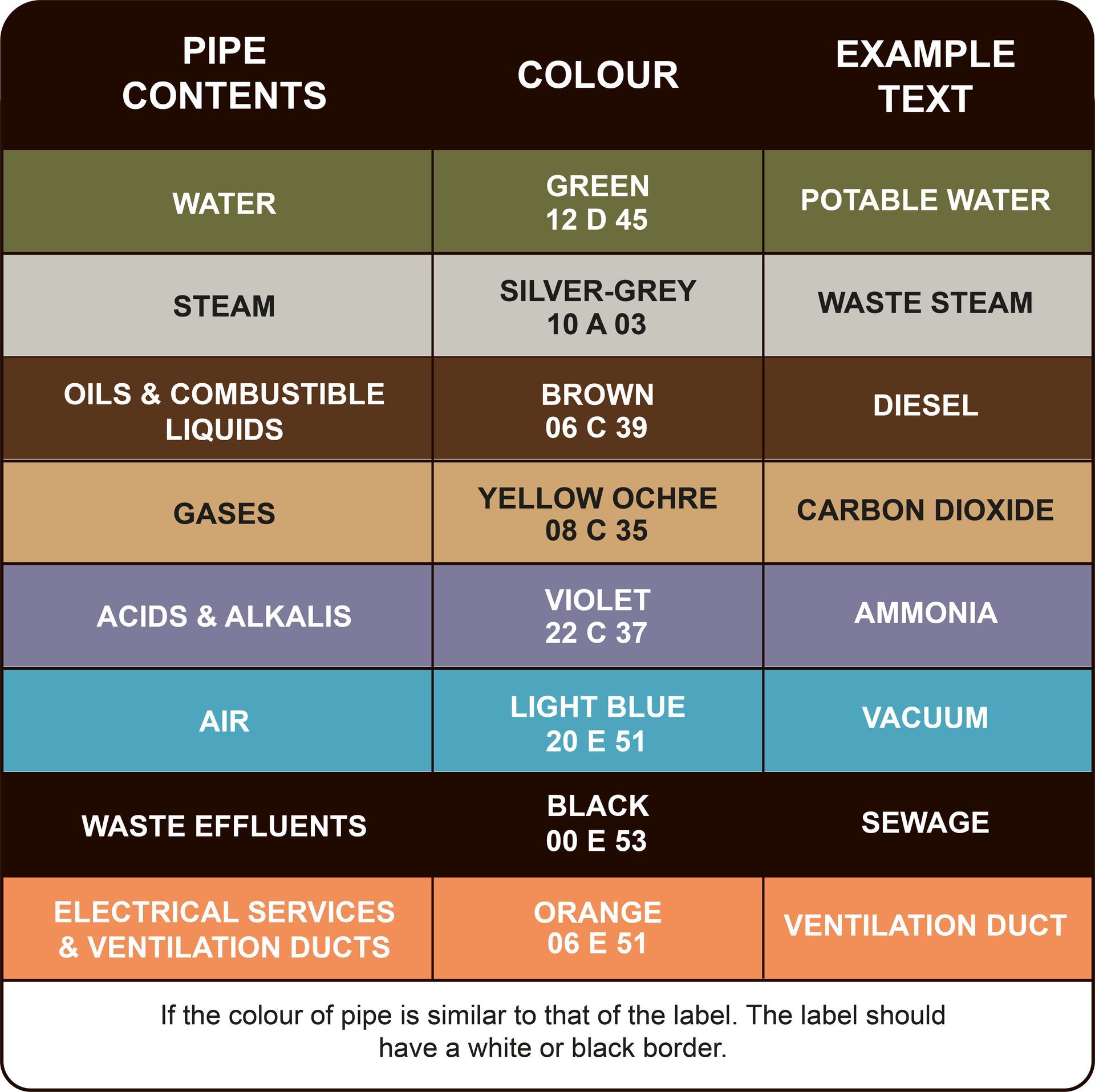

The BS1710:2014 standard utilises a system of 8 Basic colours to identify the basic contents of the pipe, then further colour banding may identify quality, properties, uses and help to further distinguish the contents.

Basic Identification Colours (BIC)

Basic Indication Colours (BIC) are used to indicate the general content of the pipe.

Text provides specific content information and arrows show the direction of flow. Safety and code colours are applied in bands as explained further along in this article.

All colours are specified from BS4800

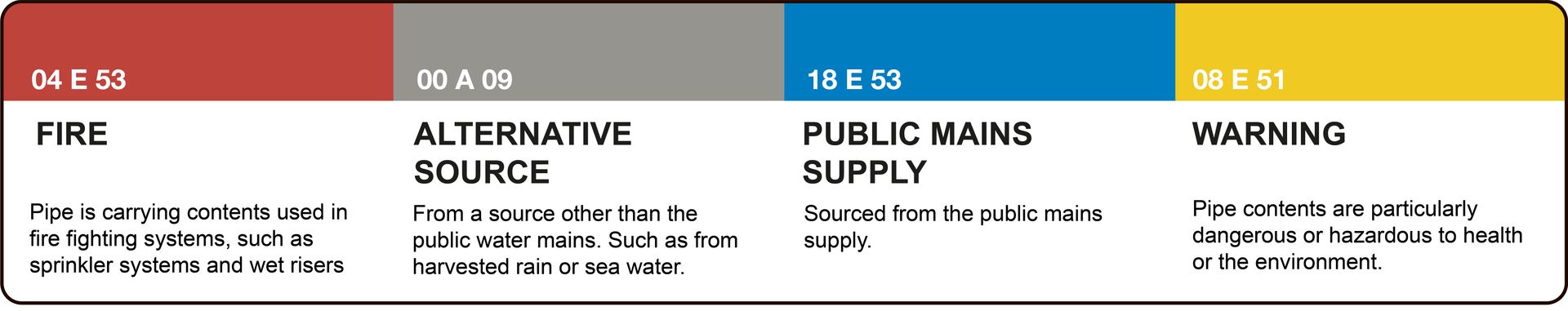

Safety Colours

Code & Other Colours

These colours are used when there are regulations that are required to be met in specific industries or in specific contexts. BS1710:2014 has incorporated these into the standards.

This means that the correct implementation of pipe marking according to BS1710:2014 will also ensure your pipe marking also meets the requirements of:

•

Building Regulations (Parts L & G);

•

F-Gas Regulations (EU/UK law)

•

HTM 02-01 (UK NHS)

Alongside meeting the requirements of

Health & Safety (Signs and Signals) Regulations 1996.

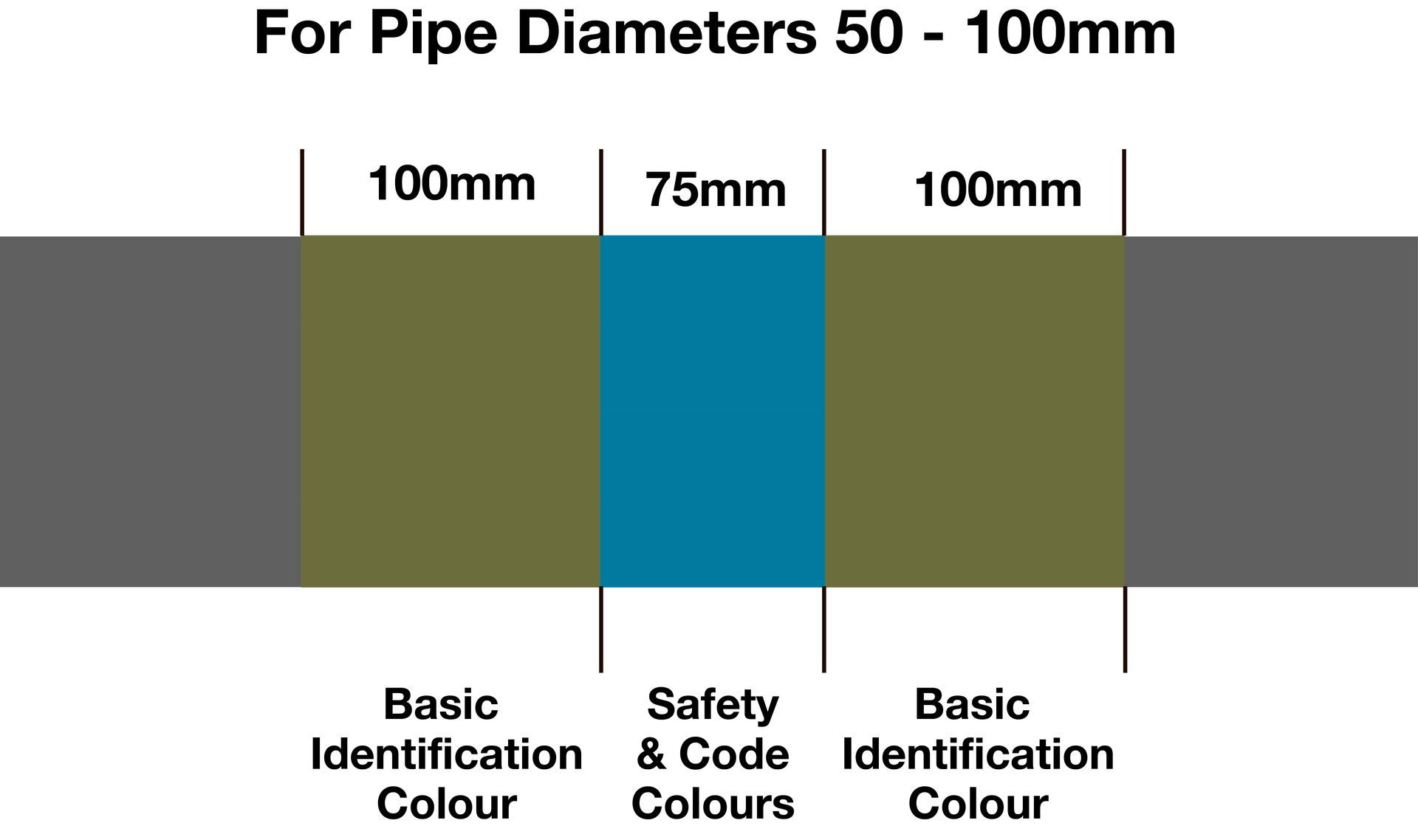

Marker Sizes & Basic Marker Design Specifications

BS1710:2014 sets standards for design, size and positioning of colour coding markers on pipelines to ensure safety and compliance to the applicable regulations.

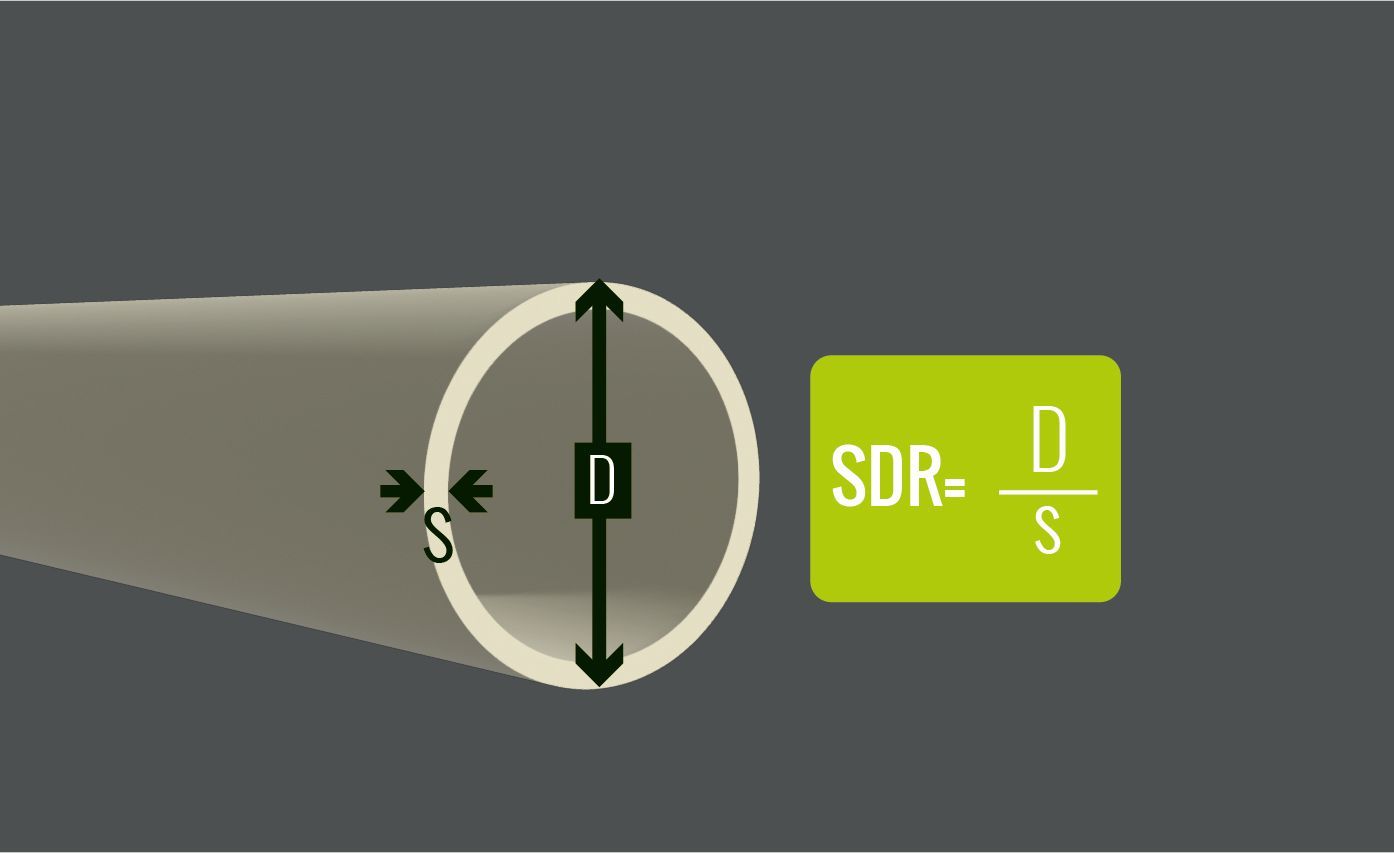

Sizes of Colour Coding Markers

| Pipe Diameter <50mm | Pipe Diameter 50-100mm | Pipe Diameter >100mm | |

|---|---|---|---|

| Basic ID Colour | 50mm | 100mm | 150mm |

| Safety / Code Colours | 30mm | 75mm | 150mm |

| Total Marker Width | 130mm | 275mm | 450mm |

BS1710 sets out standards on the size of the colour banding required, dependant on the diameter of pipe being marked.

The diagram here shows the basic design principle of the banding.

- The Basic Identification Colour may be used alone in some circumstances and the BIC would constitute the whole of the total marker width.

- When Code and/or Safety Colours are to be used in the marker; it should follow the principle shown. The marker design should have the BIC equal on either side of the code or safety colours. The chart here shows the correct banding widths for the various pipe diameters.

To be compliant with the standard, you must use the correct size marking for the diameter of pipe being marked, include the thickness of any lagging in your calculations.

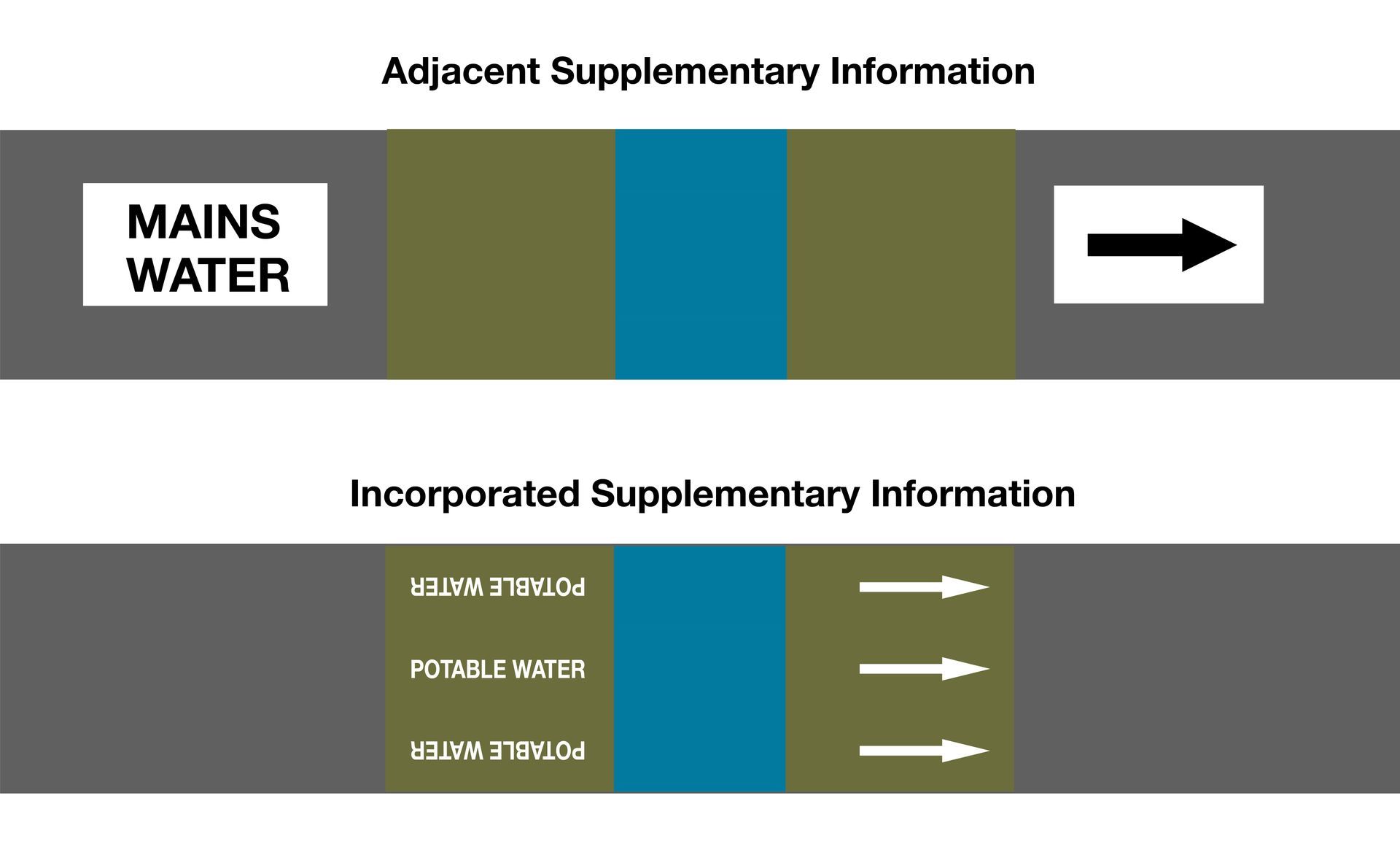

Supplementary information is also required by the standards such as direction of flow and the pipe contents described as text. PWUK

Text & Supplementary Information

BS1710

requires supplementary information to the colour bands so that a pipe marker is unambiguous.

• Flow Direction Arrows

Mandatory if flow is not otherwise obvious

•

Text Legend

Mandatory for all pipes. Must identify the contents in

clear words. Can be any of, or a combination of the listed formats:

PWUK

• Name in Full,

• Abbreviation of Name

• Chemical Symbol

• Condition Data

Pressure /

Temperature /

Concentration where these factors are important for safety or operation, they must be included in the

text legend.

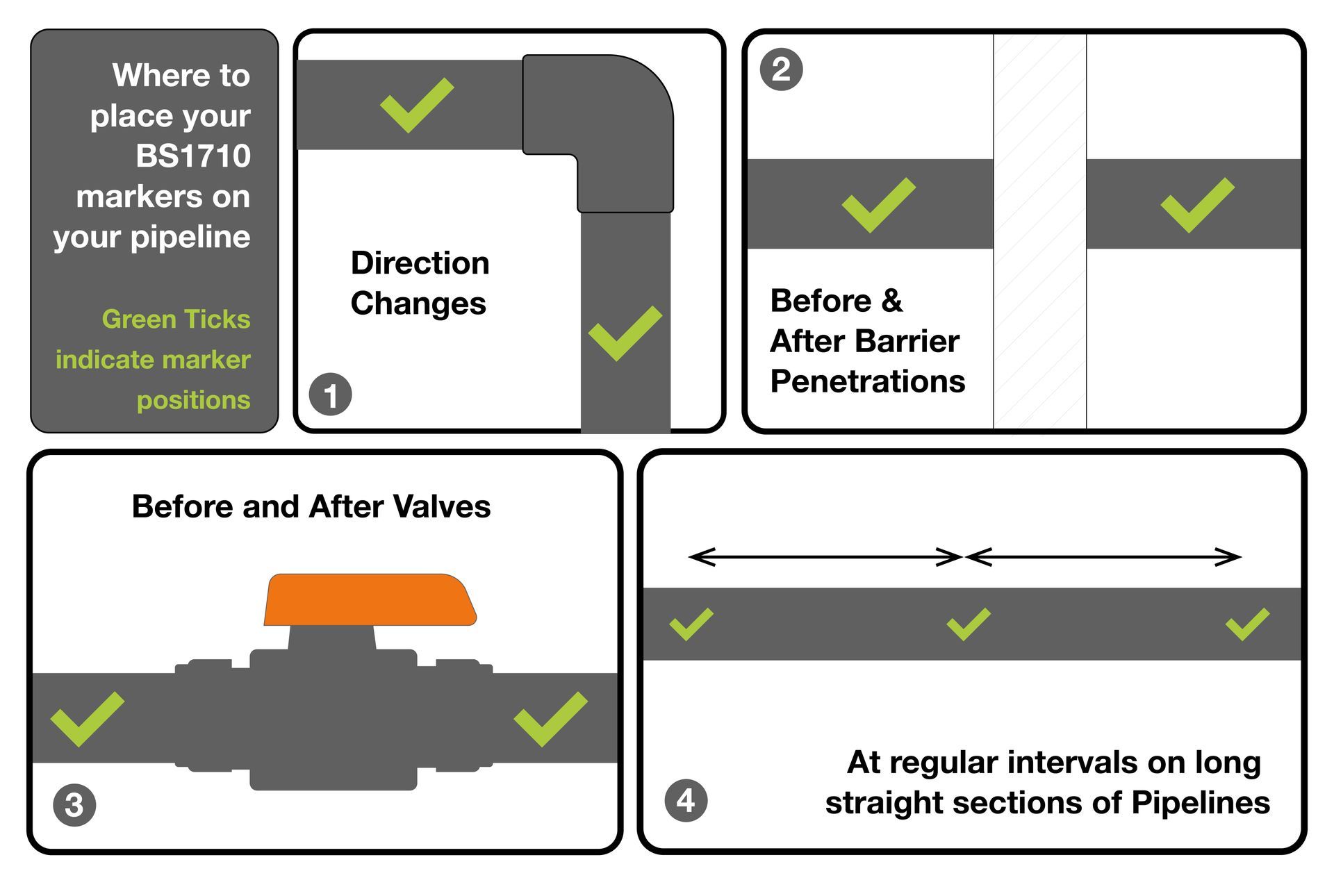

Placement of BS1710 Pipe Markers in your Pipeline

BS1710:2014 sets standards for the placement of identifying markers. To be compliant with the standards; you must position markers wherever possible in the following indicated conditions and wherever else that identification is necessary for safety.

Conditions for identifying positions to place BS1710 pipe markers

1 - Direction Changes

When the pipeline changes direction a marker should be placed

2 - Before and After Barrier Penetrations

This could mean as a pipe travels through a wall it would require a marker as it enters and exits, so that it is identifiable from both sides. This also applies to instances where a pipe travels through floor joists, a marker should be placed in every section between floor joists, to ensure identification no matter which area is exposed during future maintenance.

3 - Before & After Valves PWUK

Many systems have clusters of valves (manifolds, distribution headers, bypass loops) - Placing markers ensures every valve’s function is obvious at a glance. A marker after the valve confirms that the downstream leg carries the same substance (or indicates if it changes — e.g. mixing or branch lines). Markers at valves make emergency isolation fast and unambiguous.

4 - At Regular Intervals along straight sections of pipe

The BS1710:2014 doesn't specify a particular interval distance, but the common guidance adopted from the standard + HSE practice is:

- Every 3–5 m indoors (plantrooms, service corridors, workshops).

- Every 8–10 m outdoors (open pipe racks or where pipes are easily visible).

- Always within sight — a person standing anywhere along the pipeline should be able to see at least one identification marker.

See the Pipe Warehouse UK range of Pipe Marking Rolls

All information provided in this article is intended as a preliminary guide only. The information contained herein does not constitute advice and some subjects briefly mentioned in this article may need further research to be fully understood. Pipe Warehouse UK is not responsible for any issues arising from the use or reliance on the information contained in this article.